Most of the woodworking is complete. The weather needs to cooperate a little more before I do the staining and final assembly. This means the legs can be fabricated. Since they are metal, weather is not as much of a factor. 1”x3” rectangular tubing will be the main structure of desk. After cutting and welding, there should be plenty of strength to hold up the heavy desk.

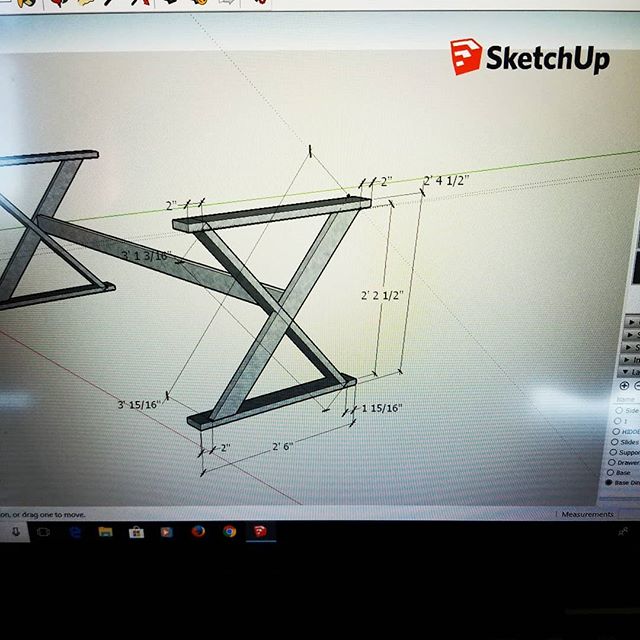

SketchUp is showing it’s power again. Rather than just guess and fabricate on the fly, a drawing was made to simulate the leg structure. Adding dimensions told me what lengths will be needed. A plugin to SketchUp gave me a cut list. The cuts didn’t take long, and then the angles will be soon following.