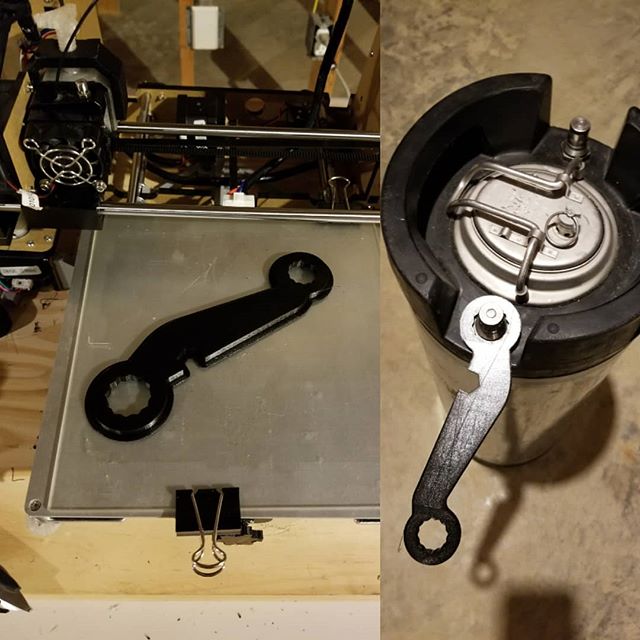

This is the second time I have printed this wrench. The first time I used ABS filiment. Half way through the print it lifted from the print bed. This time I used PLA, and it worked out great. I tried it on a couple kegs I had sitting around and it loosened the posts. I don’t think I will try and use the full length for leverage (it *is* plastic) but for the price, I can print a few. I found the object on thingiverse.com It was printed with 20% infill.

Rockler, Novi

This was a first visit to the store for me. There is a bunch of products to touch and feel. While I got a bunch of ideas, I left without buying anything. It’s not surprising as I am in the middle of another project. This store will be another resource for the long list of projects I have lined up.

Adding rubber grip on #3d printed push block.

A while back I used the 3D printer to make this push block to use mainly on the table saw. I found the design of the push block on thingiverse.com and it took around 40 hours of printing time. Fast forward to today. I am doing one of the last steps. The push block on it’s own does not hold the wood very well. I am putting a little rubber on the bottom. It is a material I found at a big box store with the drawer liners. Hopefully, it grips the wood better.

Side note: I received a MIcro Jig branded push block as a gift. It is a little smaller, but the rubber material they use is really good. So, now I have an original, and a 3D printed version. I may have $20 invested in the one I printed. This is an example of the power of a 3D printer. Sure, you need to be patient as 3D printing is not fast. It shows that when you want a ‘thing’ you may find a freely available plan and print it rather than buying it. That being said, I don’t want to discount the original branded push block. I believe the value is in the idea, not the tangible object.