Sanding is not a glamorous part of any project. No matter how much we try to avoid it, sanding makes a huge difference in the final look of the finish. This desk will be finished with Rubio. Thankfully Rubio only needs to be sanded to 120 grit which isn’t very fine. Advanced planning and tight fit up between pieces mean there isn’t much sanding to do. My failure was not cleaning the glue sqeeze out approprately. I used a blue show towel, either dry or wet. That makes the mess worse. This means I sand. A trick I learned recently (too late for this project) is to let the glue dry for about 15 minutes and then run a chisel under the glue. It will peel the glue right off. Next time.

#tbt – Couple years ago I welded a custom dog kennel to go in the custom cabinets.

At my old house I made a bunch of custom cabinets with frame and panel doors. I left a space for a place to keep the dog while I was at work. The original kennel had wood and metal which didn’t hold up well. It was time to make a dog prison. The metal supplier sold me some square tubing and 0.25” metal rod. That’s right, this prison will have bars. Welding the pieces was easy, but very time consuming. I mainly TIG welded the metal. It was rather difficult to get the final product in the basement, but once in place, it fit well. Knowing how heavy the metal would be, a wheel was added to the door to make it easier to open.

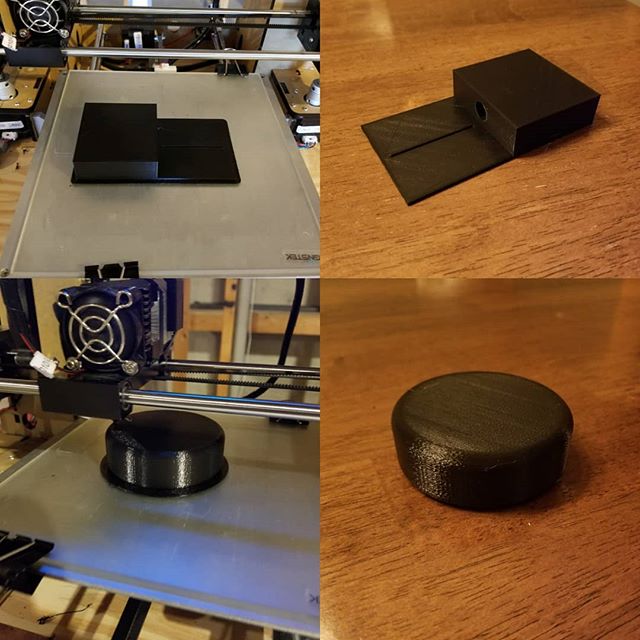

Dowel Jig and Bench Cookie.

I have been 3d printing many things. It seems there isn’t a weekend that goes by where the printer isn’t melting plastic. Usually, I am downloading objects from Thingiverse that help other projects. These are two things that I plan on using. A dowel jig can help align glueups. It is a simple jig to clamp on a piece of wood and use a hand drill to make a hole for a dowel. The other piece is a bench cookie. It holds a piece of woodwork off of the bench for sanding and finishing. These are new to me and we’ll see how well they work.