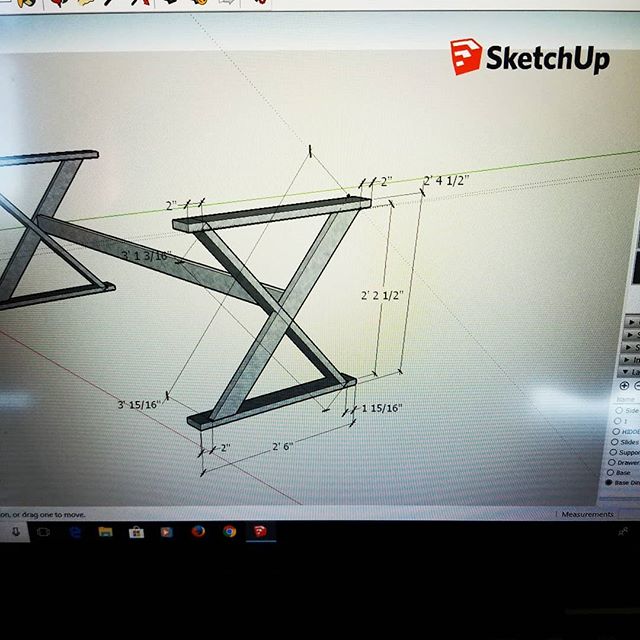

Switching over to metal for the desk legs.

Most of the woodworking is complete. The weather needs to cooperate a little more before I do the staining and final assembly. This means the legs can be fabricated. Since they are metal, weather is not as much of a factor. 1”x3” rectangular tubing will be the main structure of desk. After cutting and welding, there should be plenty of strength to hold up the heavy desk.

SketchUp is showing it’s power again. Rather than just guess and fabricate on the fly, a drawing was made to simulate the leg structure. Adding dimensions told me what lengths will be needed. A plugin to SketchUp gave me a cut list. The cuts didn’t take long, and then the angles will be soon following.

Porta-band turned vertical.

Having a porta-band has made life a bunch easier. As you notice in the picture below, it is not an expensive brand tool. This is as cheap as they come. This porta-band is a Harbor Freight buy that has been priceless for me. Being able to cut metal with no sparks and somewhat an increase in accuracy, makes the fit-up better. I have only been clamping the material to a bench and holding the saw in my hands, until now. Recently, there have been a few posts on Instagram of people’s shops, and I noticed the saw hanging on the wall. Genius. With the hooks already hanging around the shop (heh) holes were drilled in a post and the hung the saw. At first I thought is was rather loose, but when using it, the saw is secure and *should* not fall. This setup will help with the desk project and other projects in the future.